LUBRICATION

For dry type pumps (graphite vanes):- NO OIL TO BE USED.

For oil lubricated type pumps:-Use 30 grade lubrication oil. Give a few drops of the recommended oil to the pump from the vacuum side spout or oil cap periodically, eg. 8 to 10 drops once or twice in 8 hours working to keep the rotating parts lubricated. The pumps provided with oil cups should be filled with oil periodically. It is recommended to give a little oil before stopping the pump so that the rotating parts will remain oiled when not in use.

VACUUM AND PRESSURE CONNECTIONS

Use pressure tubes and tested pipes for vacuum and pressure connections. It is recommended to use the least possible lengths of tube or pipes. See that no connection or couplings is leaking. They must be air/vacuum tight. Do provide pressure switch with proper settings of cutoff value of pressure for the pumps.

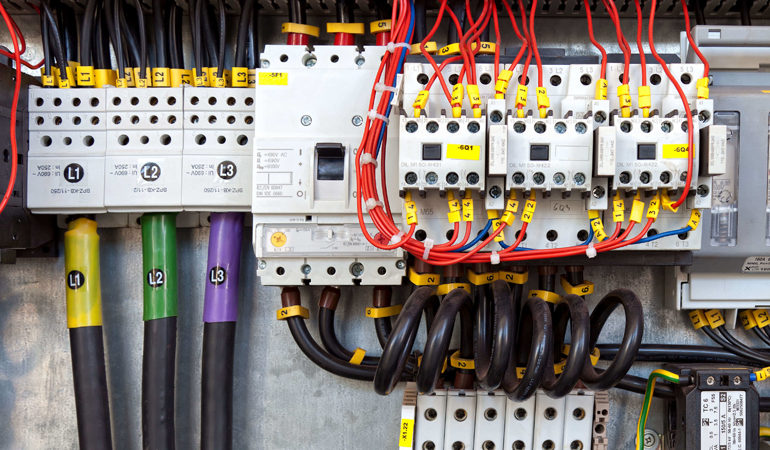

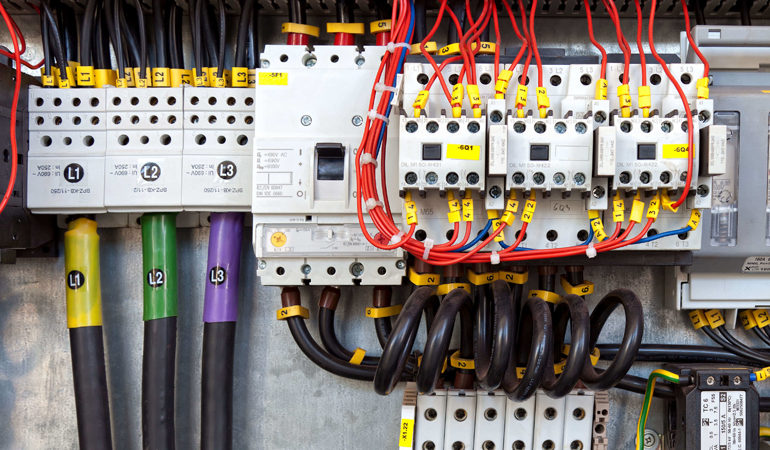

ELECTRICAL CONNECTIONS

The single phase motors belt driven or coupled to the pumps are set in right direction. In case of three phase motors, an arrow mark on the pump cover or on guard denotes the direction of rotation. When connecting the motor, check the direction. Do provide starters for three phase motors and overload replays for single phase motors.

PRECAUTIONS

Always use proper TRAPS and FILTERS on the vacuum side. See that only dry air enters the pumps. When the pump is use for pressure, set the adjustable pressure relief valve fro desired pressure. Do not exceed the recommended pressure.

FOUNDATION

The pumps should be installed in proper manner with solid foundation and proper air- ventilation for providing cooling to the motors of the pump set and should not be installed in area having ambient temperature higher than normal room temperature

MAINTENANCE

All moving parts of the pump set should be lubricated every three months over and above what is stated for oil lubricated types of pumps. Periodically, the supply voltage should be checked and confirmed that the voltage supply for electric motor of the pump set is well within the required range stated on the name plate of the electric motor. Once a month it should be checked that these are no unusual sound connecting while pump set is in running. Once every year get the pump set serviced by a reliable source.